Why cut a balloon line?

The most common reason is to terminate a balloon flight by separating your payload from the balloon. The HAB Cutter is designed as a lightweight line cutter for use on balloon flights. On more advanced flights there are a variety of other reasons to cut a line:

Example 1: tandem balloon launches are a simple and accessible altitude control method that suspends your payload below two balloons during launch. One balloon (tow) provides the free-lift necessary for a rapid ascent. While the other balloon (float) provides just enough lift to achieve neutral buoyancy for your payload. At the desired altitude the tow balloon is cut away, permitting the float balloon to hold the payload at a constant altitude.

Example 2: to deploy something during the flight. Examples include long arrays of instruments, solar panels, or drop a predefined amount of ballast.

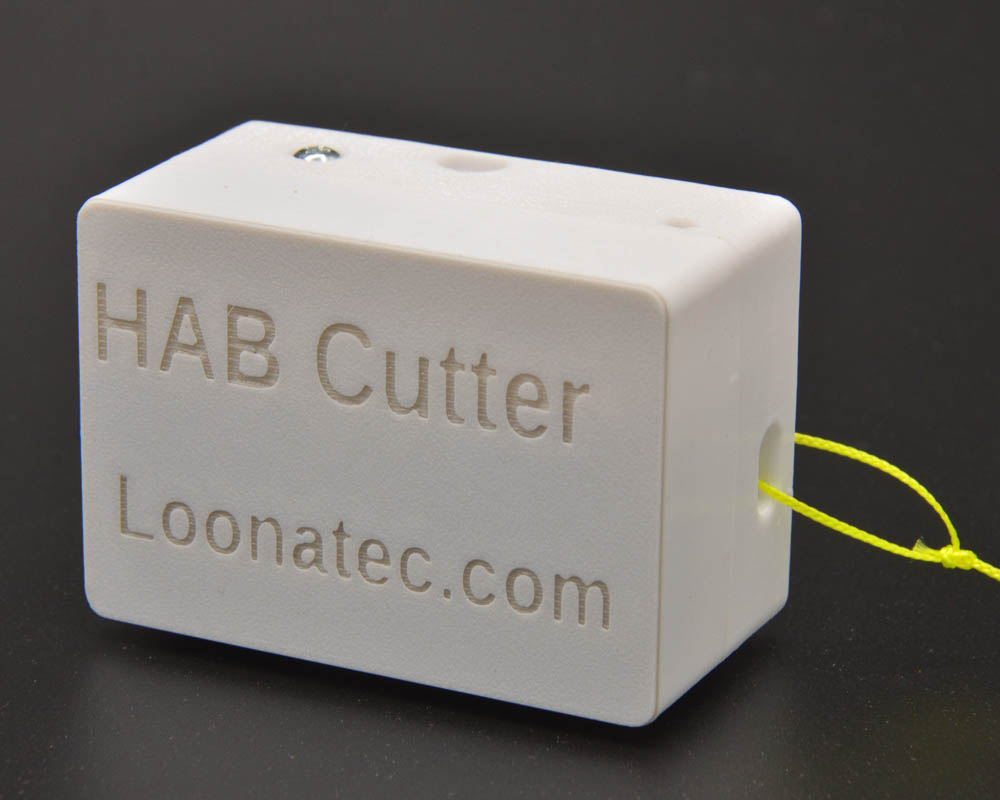

How do you control the HAB Cutter?

The HAB Cutter can be controlled via the following interfaces: 1) short-range LoRa, 2) Bluetooth Low Energy (BLE), and/or 3) wired UART. The command structure is simple and in ASCII to permit control by either a flight computer or human operator. It can be monitored and tested while on the ground using a smart-phone app, even when a flight computer is already controlling it.

The HAB Cutter has a internal timer that can be set at launch to provide a pre-determined termination event on flights without a flight computer. This helps protect against drifting too far if the flight has a slower than expected ascent rate (underinflated balloon).

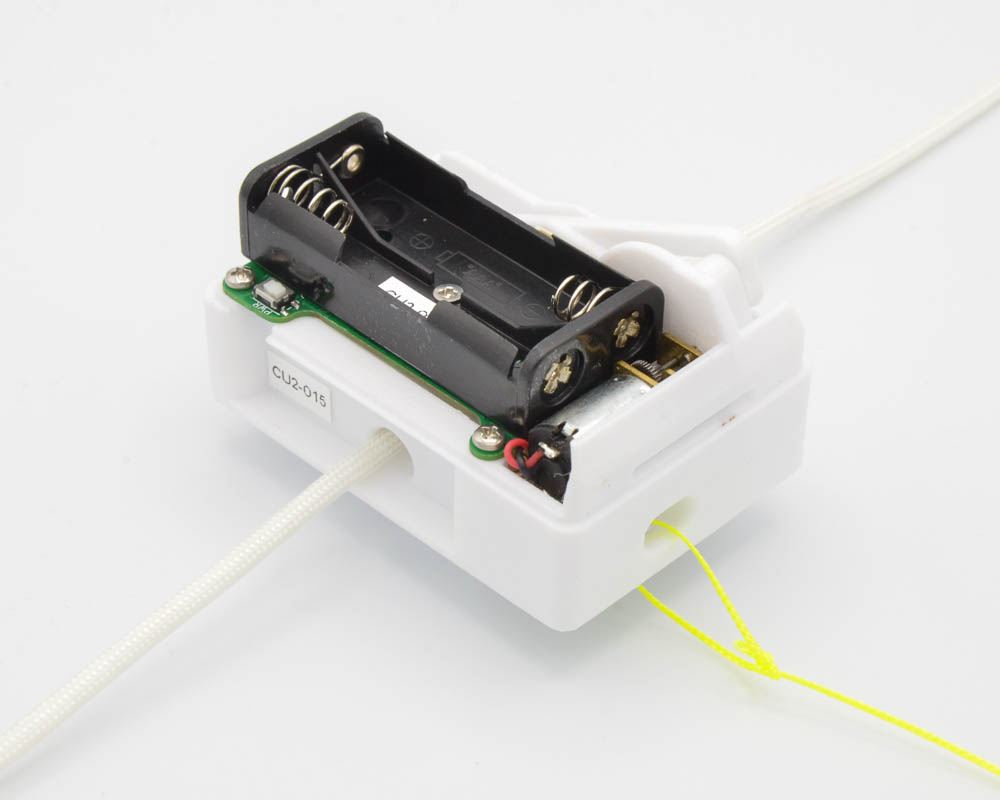

Two cold-protected batteries on the HAB Cutter provide the necessary power for flights up to two days. For longer-duration flights, additional batteries or solar panels can be added.

What line would we recommend?

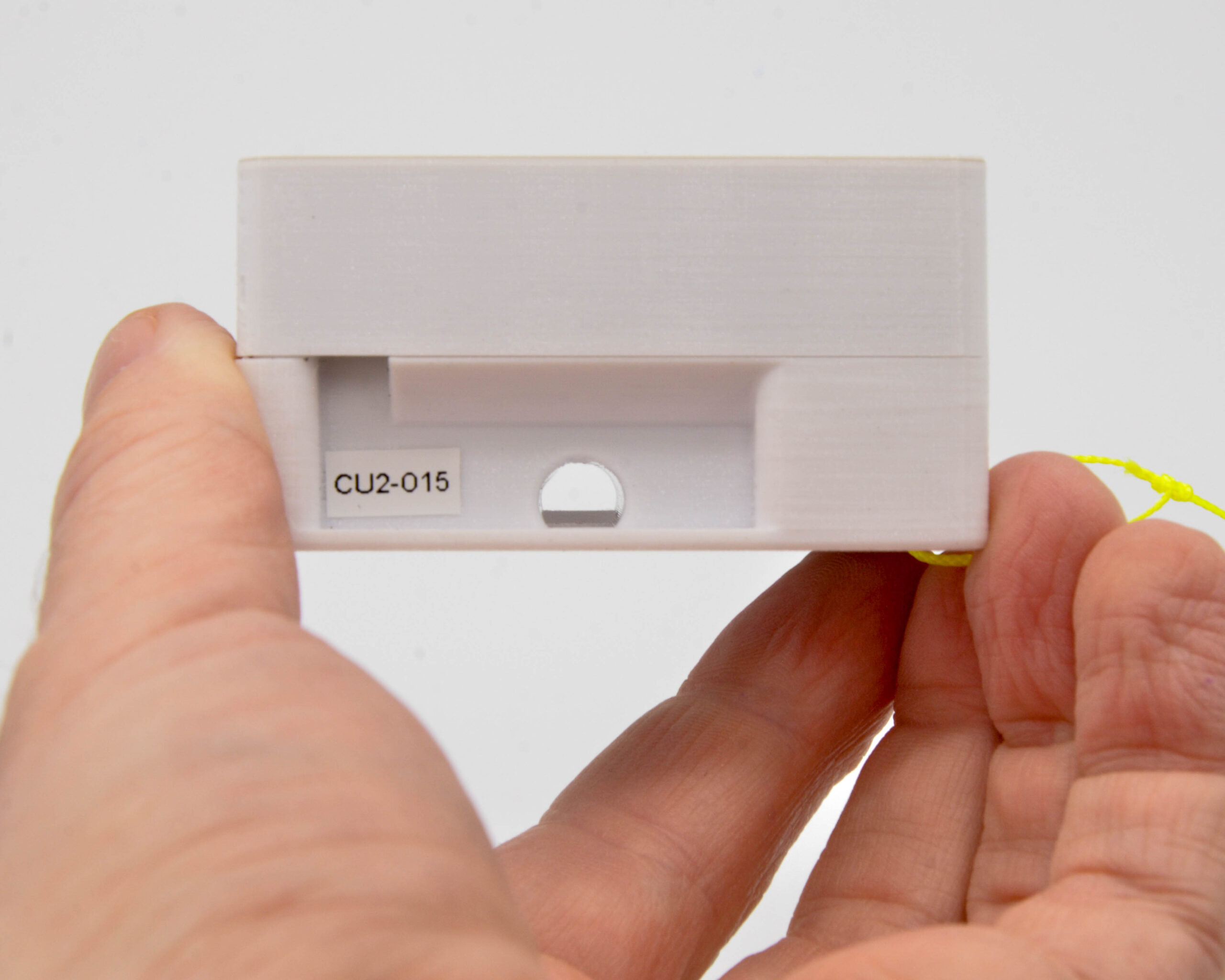

The HAB Cutter’s mechanical cutter is designed to cut through nylon suspension line (aka paracord). Any line that can be readily cut with a knife such as Nylon, Dacron, polypropylene, and polyester variants are all good candidates. If you are looking to cut through very small lines then the HAB Igniter with its burn-wires is a better choice. Similarly, if you are looking to cut through metal cables then the HAB Igniter with a pyrotechnic cutter is a better choice.

Paracord Varieties:

- Type I: Tensile strength 45 kg (100 lbs), 1.8 mm diameter

- Type II: Four inner strands, tensile strength 180 kg (400 lbs), 3.2 mm diameter

- Type III: Seven inner strands, tensile strength 250 kg (550 lbs), 4.8 mm diameter

- Type IV: Eleven inner strands, tensile strength 340 kg (750 lbs), 4.8 mm diameter

- Type V: Fourteen Inner strands, tensile strength 455 kg (1000 lbs), 6.35 mm diameter

Be aware when purchasing paracord that the consumer variants may not meet the listed tensile strengths. It is safest to purchase it directly from a reputable supplier. Below are some of the suppliers we’ve used and liked.

- Para Gear: Nylon suspension line

- Atwood Rope: 550-paracord